NJIKỌ NGWA AHỊA

| Aha Ngwaahịa | Ikwà ọkpọkọ |

| Nha | Elekere aka 1/2"-36" enweghị ntụpọ (SMLS elbow), 26"-110" ejiri akwa kpaa ya. Dayameta kachasị ukwuu n'èzí nwere ike ịbụ 4000mm |

| Ọkọlọtọ | ANSI B16.9, EN10253-2, DIN2605, GOST17375-2001, JIS B2313, MSS SP 75, wdg. |

| Ọkpụrụkpụ mgbidi | STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS na ndị ọzọ. |

| Ogo nzere | 30° 45° 60° 90° 180°, wdg |

| Redịọs | LR/ogologo radius/R=1.5D,SR/Mkpụmkpụ radius/R=1D |

| Ọgwụgwụ | Bevel end/BE/buttweld |

| Elu | agba okike, varnish, eserese ojii, mmanụ mgbochi nchara wdg. |

| ihe | Igwe carbon:A234WPB, A420 WPL6 St37, St45, E24, A42CP, 16Mn, Q345, P245GH, P235GH, P265GH, P280GH, P295GH, P355GH wdg. |

| Ígwè ọkpọkọ:ASTM 860 WPHY42, WPHY52, WPHY60, WPHY65, WPHY70, WPHY80 na ndị ọzọ. | |

| Ígwè alloy Cr-Mo:A234 WP11, WP22, WP5, WP9, WP91, 10CrMo9-10, 16Mo3, 12crmov, wdg. | |

| Ngwa | Ụlọ ọrụ Petrochemical; ụlọ ọrụ ụgbọelu na ụgbọ elu; ụlọ ọrụ ọgwụ, ikuku gas; ụlọ ọrụ ọkụ eletrik; ụlọ ụgbọ mmiri; ọgwụgwọ mmiri, wdg. |

| Uru | ngwaahịa dị njikere, oge nnyefe ngwa ngwa; dị na nha niile, ahaziri ahazi; mma dị elu |

NJIKWA PIPU

Ihe ndị a na-etinye n'ime ọkpọkọ ọkpọkọ dịka ọkpọkọ ígwè, tii ọkpọkọ ígwè, ihe ndị a na-akpọ "pipe ígwè", na mkpuchi ọkpọkọ ígwè. Ihe ndị a niile anyị nwere ike inye ọnụ, anyị nwere ahụmịhe mmepụta ihe karịrị afọ iri abụọ.

Ọ bụrụ na ị nwere mmasị na ihe ndị ọzọ dị na ya, biko pịa njikọ dị n'okpuru iji lelee nkọwa ndị ọzọ.

Tee Paịpụ MMIRI PỊPỌ OKPOMỌKỤ PỊPỤ Gbagọrọ Paịpụ NJIKWA EMECHI

Ịkwanye ọkpọkọ ọkpọkọ

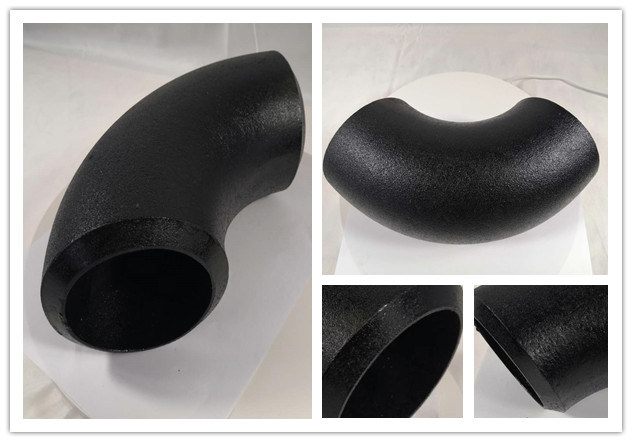

Elekere ọkpọkọ ígwè bụ akụkụ dị mkpa na sistemụ ọkpọkọ iji gbanwee ntụziaka mmiri mmiri. A na-eji ya ejikọta ọkpọkọ abụọ nwere otu ma ọ bụ dayameta aha dị iche iche, ma mee ka ọkpọkọ ahụ tụgharịa gaa n'akụkụ ụfọdụ nke ogo 45 ma ọ bụ ogo 90.

Maka ikpere aka ọkpọkọ ụlọ ọrụ mmepụta ihe, ụdị njedebe njikọ ahụ bụ njikọta butt, dịka ANSI B16.25 si kwuo. A pụrụ ịkọwa njikọta butt, njikọta butt, na njedebe bevel.

Ụdị ikiaka

Enwere ike ịchọta ikpere aka site na nkuku ntụziaka, ụdị njikọ, ogologo na radius, ụdị ihe.

Nkewa site na Nkuku Ntuziaka

Dịka anyị maara, dịka ntụzịaka mmiri si dị na paịpụ mmiri, a pụrụ ikewa ikpere aka n'ọkwa dị iche iche, dịka ogo 45, ogo 90, ogo 180, nke bụ ogo ndị a na-ahụkarị. E nwekwara ogo 60 na ogo 120, maka ụfọdụ paịpụ pụrụ iche.

Maka ikpere aka nke ogo 90, a kọwakwara ikpere aka nke ogo 90d, ma ọ bụ ikpere aka nke ogo 90d.

Gịnị bụ elbow radius

Mgbada ikpere aka pụtara mgbada. Ọ bụrụ na radius ahụ dị ka dayameta paịpụ, a na-akpọ ya radius dị mkpụmkpụ, nke a na-akpọkwa SR elbow, nke a na-ejikarị eme ihe maka ọkpọkọ dị ala na obere ọsọ.

Ọ bụrụ na radius ahụ buru ibu karịa dayameta paịpụ, R ≥ 1.5 Dayameta, mgbe ahụ anyị na-akpọ ya radius ogologo ikpere aka (LR Elbow), nke a na-etinye maka paịpụ nrụgide dị elu na ọsọ mmiri dị elu.

Ọ bụrụ na radius karịrị 1.5D, a na-akpọ ya mgbagọ. ihe ndị e ji emechi ọkpọkọ ikpere aka. Dịka elbow 2d, mgbagọ 2d, elbow 3d, mgbagọ 3d, wdg.

Nhazi site na ihe

Ígwè carbon, nke a na-akpọkwa ígwè dị nro ma ọ bụ ígwè ojii. Dịka ASTM A234 WPB

Ị na-achọ elekere igwe anaghị agba nchara, biko pịa njikọ a iji chọta nkọwa ndị ọzọ:Nkịtị ígwè anaghị agba nchara

Ụdị Ụdị

Nwere ike ịbụ ikpere aka hà nhata ma ọ bụ ime ka ikpere aka belata

IHU EKWE AKA

Mgbawa ájá

Mgbe anyị kpụchara ọkụ, anyị na-ahazi ájá iji mee ka elu ahụ dị ọcha ma dị ire ụtọ.

Mgbe ájá gbawara, iji zere nchara, e kwesịrị iji agba ojii ma ọ bụ mmanụ mgbochi nchara, ihe na-ekpo ọkụ na-etinye galvanized (HDG), epoxy, 3PE, ihe dị n'elu ya furu efu, wdg. Nke ahụ dabere na arịrịọ onye ahịa.

Ọgwụgwọ Okpomọkụ

1. Debe ihe ndị dị mkpa ka e jiri ha chọpụta.

2. Hazie ọgwụgwọ okpomọkụ dịka ọkọlọtọ siri dị.

MAKA

Ọrụ akara dị iche iche, enwere ike ịgbagọ agbagọ, eserese, na ihe e ji akara mee. Ma ọ bụ dịka ị rịọrọ. Anyị na-anabata akara LOGO gị.

Foto zuru ezu

1. Ngwụcha Bevel dịka ANSI B16.25 si dị.

2. Jiri ájá gbaa ya mbụ, wee see ya nke ọma. E nwekwara ike iji varnish tee ya.

3. Na-enweghị lamination na mgbawa.

4. Na-enweghị ndozi ọ bụla nke njikọta.

NYOCHA

1. Nha nha, ihe niile dị n'ime nnabata ọkọlọtọ.

2. Ntachi obi: +/-12.5%, ma ọ bụ dịka arịrịọ gị si dị

3. PMI

4. Nnwale MT, UT, na X-ray

5. Nabata nyocha nke ndị ọzọ

6. Asambodo MTC nke Supply, EN10204 3.1/3.2

NKWEKỌTA NA MBUPUTA

1. Ejiri plywood case ma ọ bụ plywood pallet jupụta ya dịka ISPM15 si dị

2. Anyị ga-etinye ndepụta nkwakọ ngwaahịa na ngwugwu ọ bụla

3. Anyị ga-etinye akara mbupu na ngwugwu ọ bụla. Okwu akara dị na arịrịọ gị.

4. Ihe niile e ji ekpofu osisi anaghị agba ọkụ

Ajụjụ Ndị A Na-ajụkarị

1. Gịnị bụ ANSI B16.9?

ANSI B16.9 na-ezo aka na ọkọlọtọ American National Standards Institute (ANSI) maka ihe ndị e ji arụ ọrụ n'ụlọ ọrụ mmepụta ihe. Ọ na-akọwapụta nha, nguzogide, ihe ndị e ji arụ ọrụ na ihe achọrọ maka nnwale maka ihe ndị e ji arụ ọrụ n'ubu.

2. Gịnị bụ ihe ndị e ji ọkpọkọ ọkpọkọ rụọ?

Ihe ndị e ji ejikọ ọkpọkọ n'úkwù bụ ihe ndị e ji ejikọ ọkpọkọ n'akụkụ ọkpọkọ ma ọ bụ ihe ndị ọzọ iji mepụta njikọ siri ike, nke na-anaghị agbapụta mmiri. A na-ejikọta ọkpọkọ n'úkwù site n'itinye nsọtụ ọkpọkọ ma ọ bụ itinye ya n'ime oghere ọkpọkọ ọzọ ma ọ bụ itinye ya na njikọta ahụ.

3. Gịnị bụ nkwojiaka ịgbado ígwè carbon nke ogo 180?

Ekwà aka agbatịala ígwè carbon nke ogo 180 bụ ihe e ji etinye paịpụ iji gbanwee ntụziaka nke paịpụ ahụ ogo 180. A na-enweta ya n'ụdị radius dị ogologo ma ọ bụ dị mkpụmkpụ ma e ji ihe e ji ígwè carbon mee ya. Jiri njikọ agbatị aka jikọọ ikpere aka na paịpụ ma ọ bụ ihe ndị ọzọ e ji etinye ya.

4. Kedu ihe achọrọ maka ikpere aka a na-agbakọta na ANSI B16.9?

ANSI B16.9 na-akọwapụta nha, nguzogide, ihe, na ihe achọrọ maka nnwale maka ikpere aka a gbanyere agbaze. Ọ na-enye nduzi na usoro mmepụta, gụnyere dayameta mpụta, ọkpụrụkpụ mgbidi, nha etiti ruo na njedebe na radius nke mgbagọ maka ikpere aka dị iche iche.

5. Gịnị bụ uru dị na iji ígwè carbon maka ọkpọkọ ọkpọkọ e ji agbanye n'úkwù?

A na-ejikarị ígwè carbon eme ihe n'ihe ndị e ji agbanye ọkpọkọ n'úkwù n'ihi ike ya dị mma, ogologo oge ya na iguzogide nchara. Ọ nwere ike iguzogide nrụgide dị elu na gburugburu okpomọkụ dị elu ma nwee arụmọrụ dị oke ọnụ. Ihe ndị e ji ejikọta ígwè carbon dabara adaba maka ọtụtụ ọrụ na ụlọ ọrụ mmanụ na gas, petrochemical na mmepụta ike.

6. Enwere ike iji igwe carbon nke dị ogo 180 mee ihe ma n'ime sistemụ nrụgide dị elu ma n'ime sistemụ nrụgide dị ala?

Ee, enwere ike iji ikpere aka ígwè carbon nke nwere ogo 180 mee ihe ma n'ime sistemụ nrụgide dị elu ma n'ime sistemụ nrụgide dị ala. Agbanyeghị, a ga-atụle ọkwa nrụgide kpọmkwem nke ikpere aka dabere na ihe achọrọ maka ngwa ahụ. A ga-enyocha ngwa ndị a maka ndakọrịta na nrụgide sistemụ a tụrụ anya ya.

7. Ọ dị mma ka ígwè carbon nke e ji ihe e ji agbanye ígwè nke ogo 180 mee rụọ ọrụ nke ọma maka gburugburu ebe a na-emebi ihe?

Ee, ihe ndị e ji ígwè carbon mee dị mma maka ojiji n'ebe ndị na-emebi ihe. Agbanyeghị, a ga-atụle ụdị na njupụta nke ihe ndị na-emebi ihe mgbe a na-ahọrọ ihe ndị ọzọ. N'ebe ndị na-emebi ihe karịa, a pụrụ ịchọ nchebe ọzọ, dị ka mkpuchi ma ọ bụ ihe mkpuchi dị n'èzí.

8. Enwere ike iji ọkpọkọ ígwè carbon nke ogo 180 mee ihe na paịpụ ndị e ji ihe ndị ọzọ mee?

Ee, enwere ike iji ọkpọkọ ígwè carbon nke nwere ogo 180 mee ihe na paịpụ ndị e ji ígwè anaghị agba nchara, ígwè alloy, ọla ndị na-abụghị ferrous na ihe ndị ọzọ mee. Agbanyeghị, maka arụmọrụ ogologo oge, a ga-atụle ndakọrịta dị n'etiti ihe na mmetụta nchara galvanic nwere ike inwe.

9. Kedu ule emere na ANSI B16.9 carbon steel nke ogo 180?

ANSI B16.9 na-akọwapụta ule dị iche iche iji hụ na e ji ígwè carbon rụọ ọrụ nke ọma ma kwụsie ike. Ule ndị a nwere ike ịgụnye nyocha nha, nyocha anya, nyocha ultrasonic, nnwale ike nrụgide, nnwale mmetụta na nnwale na-anaghị emebi emebi (dịka ntinye agba ma ọ bụ nyocha redio).

10. Enwere ike ịgbanwe ma ọ bụ dụkọta ikpere aka ígwè carbon nke ogo 180 n'ebe ahụ?

Enwere ike ịgbanwe ma ọ bụ dụkọta ikpere aka ígwè carbon nke ogo 180 n'ọhịa mana ndị ọrụ ruru eru na ndị nwere ahụmịhe kwesịrị ime ya dịka ụkpụrụ na usoro ụlọ ọrụ si dị. A na-atụ aro ka ị gakwuru onye nrụpụta ma ọ bụ injinia ọkachamara maka nduzi iji hụ na nchekwa na arụmọrụ nke ngwa ndị agbanwere agbanwe.

Ihe ndị dị mkpa maka paịpụ bụ ihe ndị dị mkpa na sistemụ paịpụ, a na-eji ha ejikọ, na-emegharị ya, na-agbanwe ya, na-agbanwe nha ya, na-emechi ma ọ bụ na-achịkwa mmiri mmiri. A na-ejikarị ha eme ihe n'ọhịa dịka ihe owuwu, ụlọ ọrụ mmepụta ihe, ike na ọrụ obodo.

Ọrụ Ndị Dị Mkpa:Ọ nwere ike ịrụ ọrụ dịka ijikọ paịpụ, ịgbanwe ụzọ mmiri si aga, kewaa na ijikọ mmiri si aga, ịgbanwe dayameta paịpụ, mechie paịpụ, ijikwa na ịchịkwa mmiri si aga.

Oke Ngwa:

- Mmiri na draịva ụlọ:A na-eji ikpere aka PVC na PPR tris eme ihe maka netwọk ọkpọkọ mmiri.

- Paịpụ ndị ọrụ mmepụta ihe:A na-eji ihe mkpuchi ígwè anaghị agba nchara na ihe mkpuchi ígwè alloy eme ihe iji bufee ihe mkpuchi kemịkalụ.

- Njem ike:A na-eji ihe ndị e ji ígwè rụọ arụ ọrụ nke nwere nrụgide dị elu na paịpụ mmanụ na gas.

- HVAC (Ịkpo oku, ikuku ikuku, na ntụ oyi):A na-eji ihe ndị e ji ejikọta paịpụ ọla kọpa iji jikọọ paịpụ ndị na-eme ka mmiri dị jụụ, a na-ejikwa njikọ ndị na-agbanwe agbanwe eme ihe maka ibelata ịma jijiji.

- Ịgba mmiri n'ugbo:Njikọ ngwa ngwa na-eme ka mgbakọ na mwepụ nke sistemụ ịgba mmiri sprinkler dị mfe.

-

90 ogo ikiaka tee reducer carbon ígwè Butt w ...

-

eriri carbon sch80 butt welded end 12 inch sch4...

-

Asme b16.9 usoro ihe omume 80 ígwè ọkpọkọ ihe kwesịrị ekwesị tee ...

-

carbon ígwè concentric reducer astm a105 Black...

-

ANSI B16.9 Carbon Steel 45 Degree Welding Bend

-

Eriri ígwè anaghị agba nchara ogologo bend1d 1.5d 3d 5d radius 3...