Nkọwapụta

| Aha Ngwaahịa | Njikọta ụkwụ/Fenji dị nro |

| Nha | 1/2"-24" |

| Nrụgide | 150#-2500#,PN0.6-PN400,5K-40K |

| Ọkọlọtọ | ANSI B16.5, EN1092-1, JIS B2220 wdg. |

| Ọgwụgwụ isi stub | MSS SP 43, ASME B16.9 |

| ihe | Igwe anaghị agba nchara:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571, 1.4541, 254Mo na wdg. |

| Igwe carbon:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 wdg. | |

| Igwe anaghị agba nchara duplex:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462, 1.4410, 1.4501 na ndị ọzọ. | |

| Ígwè ọkpọkọ:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 wdg. | |

| Ngwongwo nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 wdg. | |

| Ngwakọta Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3, 15Crmo, wdg. | |

| Ngwa | Ụlọ ọrụ mmanụ ala; ụlọ ọrụ ụgbọelu na ụgbọ elu; ụlọ ọrụ ọgwụ; ikuku gas; ụlọ ọrụ ike; ụlọ ọrụ ụgbọ mmiri; ọgwụgwọ mmiri, wdg. |

| Uru | ngwaahịa dị njikere, oge nnyefe ngwa ngwa; dị na nha niile, ahaziri ahazi; mma dị elu |

Ụkpụrụ Nha

NKỌWA NGWA AHỊA

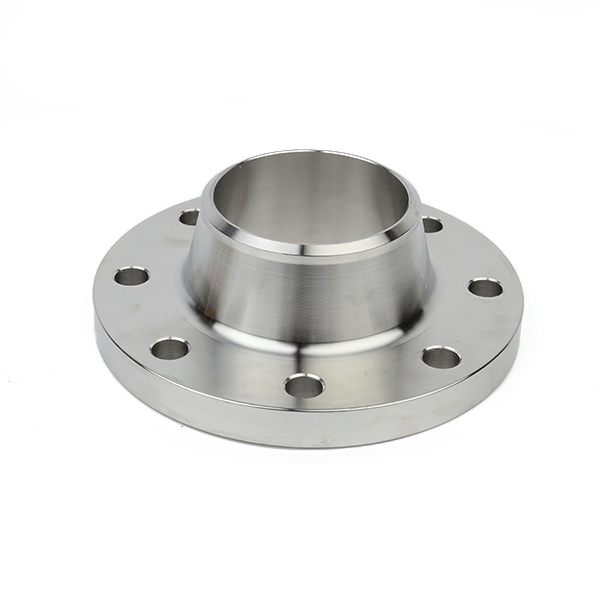

1. Ihu

Enwere ike ibuli ihu elu (RF), ihu zuru oke (FF), nkwonkwo mgbanaka (RTJ), Groove, Ire, ma ọ bụ ahaziri ya.

2. Ngwụcha Bevel dịka ANSI B16.25 si dị

3. CNC emechara nke ọma.

Mmecha ihu: A na-atụ mmecha ihu flange dị ka Arithmetical Average Roughness Height (AARH). A na-ekpebi mmecha ahụ site na ọkọlọtọ ejiri. Dịka ọmụmaatụ, ANSI B16.5 na-akọwa mmecha ihu n'ime oke 125AARH-500AARH (3.2Ra ruo 12.5Ra). Enwere ike ịchọta mmecha ndị ọzọ na arịrịọ, dịka ọmụmaatụ 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra ma ọ bụ 6.3/12.5Ra. Oke 3.2/6.3Ra bụ nke a na-ahụkarị.

ỊKARA NA NKWAKỌTA

• Jiri ihe mkpuchi plastik chebe elu nke ọ bụla

• Maka igwe anaghị agba nchara niile, a na-etinye plywood n'ime akpa. Maka nnukwu nha, a na-eji plywood pallet jupụta carbon flange. Ma ọ bụ enwere ike ịhazi ngwugwu ahụ.

• Enwere ike itinye akara mbupu na arịrịọ

• A pụrụ ịkpụ ma ọ bụ bipụta akara na ngwaahịa. A na-anabata OEM.

NYOCHA

• Ule UT

• Ule PT

• Ule MT

• Nnwale nha

Tupu nnyefe, ndị otu QC anyị ga-ahazi ule NDT na nyocha nha. Ha nabatakwa TPI (nnyocha nke ndị ọzọ).

Usoro Mmepụta

| 1. Họrọ ezigbo ihe eji arụ ọrụ | 2. Bee ihe eji eme ihe | 3. Ịkpo ọkụ tupu oge eruo |

| 4. Ịkpụcha ihe | 5. Ọgwụgwọ okpomọkụ | 6. Ịrụ ọrụ siri ike |

| 7. Ịgwupụta ihe | 8. Ịmecha nke ọma | 9. Akara |

| 10. Nnyocha | 11. Nkwakọ ngwaahịa | 12. Nnyefe |

Ikpe Mmekọahụ

Ọrụ na mba Turkey, a na-eji flanges eme ihe na paịpụ gas eke. TUV kwadoro flanges ndị ahụ niile.

Mpempe akwụkwọ data Flange

1Nha na nguzozi nke flange ga-adị ka ASME B16.5 si dị.

2. A ga-eji ihe e ji akpụ akpụ mepụta flanges.

3. Ihe ndị e ji rụọ ya ga-adị ka ọkọlọtọ ASTM A105, ASTM A694 F65 na ASTM A694 F70 si dị.

4. A ga-emenyụ ma mee ka flanges ASTM A694 F65 na ASTM A694 F70 dị nro.

5. A ga-enye asambodo nnwale ihe na akụkọ ọgwụgwọ okpomọkụ maka nyocha TPI.

6. Flanges WN ga-adị na nsọtụ bevel dịka ASME B16.25 si dị.

7. Ụkpụrụ nnwale kemịkalụ na igwe (mmetụta, mmepụta, nrụgide wdg) nke ihe ndị a ga-agbaso dịka ụkpụrụ ndị metụtara ya si dị.

8. A ga-eji mmanụ doro anya tee ihe niile dị n'elu ya ma tee ha mmanụ iji gbochie nchara ịcha.

9. Akara ga-agụnye ozi ndị a,

• Dayameta (oge 6")

• Klas nrụgide (ihe dị ka 150 LB)

• Ọkwa ihe (dịka ASTM A 105)

• Okpụrụ mgbidi (ihe dịka 4.78 mm)

• Nọmba Okpomọkụ (gwụchara 138413)

• Ụkpụrụ mmepụta (ASME B16.5)

10. Ihe ndị e ji rụọ ọrụ agaghị enwe ntụpọ na mgbawa ọ bụla n'elu ya. A machibidoro ịrụzi ihe ndị e ji agbado ọkụ kpamkpam.

11. A ga-ebuli flanges niile elu (RF) nwere elu mkpuchi. Elu mkpuchi ahụ ga-abụ Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) dịka ASME B46.1 si dị.

12. A ga-akwakọba ihe ndị e ji arụ ọrụ iji gbochie mmebi na ihe ndị e ji emechi ihe.

13. Akụkụ niile ga-adị na nguzozi dị mma (+). E wezụga nguzozi, a machibidoro ya kpamkpam.

14. A ga-eme ka flange bevellings dabara na ASME B16.25.

15. A ga-enyocha usoro mmepụta ihe n'oge ọ bụla site na TPI.

16. TPI nwere ike iwere ihe nlele site na ihe ọ bụla maka ihe nlele kemịkalụ/nnwale igwe.

17. TPI ga-enyocha akụkọ nyocha na-abata.

| ihe | Nha (Inch) | Klas nrụgide | CS | ihe | WT (mm) | Ọnọdụ | Ọnụọgụ. |

| SORF | 12 | 150LB | 20 | A105 | - | Tankị Flanges | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | Tankị Flanges | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | Tankị Flanges | 32 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 14 | Tankị Flanges | 2 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 5.54 | Tankị Flanges | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | Tankị Flanges | 6 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 5.54 | Tankị Flanges | 8 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 14 | Tankị Flanges | 8 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 16 | Tankị Flanges | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | Tankị Flanges | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | Tankị Flanges | 6 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 5.54 | Tankị Flanges | 8 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 14 | Tankị Flanges | 16 |

| ihe | Nha (Inch) | Klas nrụgide | CS | ihe | WT (mm) | Ọnọdụ | Ọnụọgụ. |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Olu Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Olu Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Olu Weld | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Olu Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Olu Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Olu Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Olu Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Olu Weld | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Olu Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Olu Weld | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Olu Weld | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Olu Weld | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Olu Weld | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Olu Weld | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Olu Weld | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

Ajụjụ Ndị A Na-ajụkarị

1. Kedu ụdị ihe eji etinye ọkpọkọ ígwè anaghị agba nchara dị iche iche?

Azịza: Ihe ndị e ji ígwè anaghị agba nchara mee gụnyere ihe ndị e ji ígwè agbado ụkwụ, ... valvụ na ụdị ndị ọzọ.

2. Gịnị bụ ihe dị iche n'etiti ihe eji etinye paịpụ ígwè anaghị agba nchara 304 na ihe eji etinye paịpụ ígwè anaghị agba nchara 316?

A: 304 ígwè anaghị agba nchara dị mma maka ọtụtụ ngwa ma nwee ezigbo iguzogide nchara. N'aka nke ọzọ, 316 ígwè anaghị agba nchara nwere ike iguzogide nchara ka mma n'ebe dị oke njọ ma dịkwa mma maka ngwa mmiri na kemịkalụ.

3. Gịnị bụ uru dị n'iji ihe e ji kpụọ ọkpọkọ e ji agbado ọkpọkọ?

A: Ngwa njikọta e ji alụ ọgụ ike, ntụkwasị obi, na njikọ na-enweghị mmiri mmiri. Ha na-enye ezigbo iguzogide mmetụta ma a na-ahọrọ ha maka nrụgide dị elu na ojiji okpomọkụ dị elu.

4. Gịnị bụ flange nke ịgbado ọkụ butt?

Azịza: Flange njikọta butt bụ flange paịpụ nke nwere etiti ogologo ma jikọta ya na paịpụ ahụ. Ọ na-enye mgbanwe dị nro site na paịpụ gaa na flange na ike na iguzosi ike n'ezi ihe.

5. Kedu ọkwa ígwè anaghị agba nchara ka a na-ejikarị eme ihe maka ihe ndị e ji ekpo ọkụ?

A: A na-ejikarị ígwè anaghị agba nchara 304, 316, 304L, 316L na 317 eme ihe na paịpụ n'ihi ezigbo iguzogide nchara, ịdịte aka na ọtụtụ ihe dị iche iche.

6. Enwere ike iji ihe eji arụ ọrụ ọkpọkọ ígwè anaghị agba nchara mee ihe n'oge okpomọkụ dị elu?

Azịza: Ee, ihe eji ejikọta ígwè anaghị agba nchara dị mma maka ojiji okpomọkụ dị elu. Agbanyeghị, a ga-ahọrọ ọkwa nke ígwè anaghị agba nchara ejiri nke ọma dabere na ihe achọrọ maka okpomọkụ nke ngwa ahụ.

7. Ihe ndị e ji ígwè anaghị agba nchara rụọ hà dị mma maka ụlọ ọrụ nri na ihe ọṅụṅụ?

Azịza: Ee, a na-ejikarị ihe ndị e ji ígwè anaghị agba nchara arụ ọrụ n'ụlọ ọrụ nri na ihe ọṅụṅụ n'ihi ịdị ọcha ha, iguzogide nchara, na mmezi ha dị mfe.

8. Gịnị bụ ihe dị iche n'etiti ihe ndị e ji agbanye socket na ihe ndị e ji agbanye butt?

Azịza: Ihe ndị e ji agbanye paịpụ socket tinye paịpụ ahụ n'ime oghere ahụ wee mee njikọ fillet iji jikọọ paịpụ ahụ. N'aka nke ọzọ, ihe ndị e ji ejikọta butt weld chọrọ ka a beveled nsọtụ paịpụ ahụ wee jikọta ya.

9. Enwere ike iji ihe eji arụ ọrụ paịpụ ígwè anaghị agba nchara mee ihe ọzọ?

A: Ee, ihe eji etinye paịpụ ígwè anaghị agba nchara nwere ike imegharị nke ọma. Ígwè anaghị agba nchara bụ ihe na-adịgide adịgide nke enwere ike imegharị ma jiri ya mee ihe ọzọ n'efunahụghị ihe onwunwe ma ọ bụ ịdị mma ya.

10. Kedu uru dị n'iji ihe eji etinye ọkpọkọ ígwè anaghị agba nchara ma e jiri ya tụnyere ihe ndị ọzọ?

A: Ihe ndị e ji ígwè anaghị agba nchara rụọ na-enye ọtụtụ uru, dịka ezigbo iguzogide nchara, ike dị elu, ịdịte aka na ihe ndị dị ọcha. Ha anaghị elekọta nke ọma, ha na-adịte aka ma na-adị ọcha ma mara mma.

NKỌWA NGWA AHỊA

1. Ihu

Enwere ike ibuli ihu elu (RF), ihu zuru oke (FF), nkwonkwo mgbanaka (RTJ), Groove, Ire, ma ọ bụ ahaziri ya.

2. Ngwụcha Bevel dịka ANSI B16.25 si dị

3. CNC emechara nke ọma.

Mmecha ihu: A na-atụ mmecha ihu flange dị ka Arithmetical Average Roughness Height (AARH). A na-ekpebi mmecha ahụ site na ọkọlọtọ ejiri. Dịka ọmụmaatụ, ANSI B16.5 na-akọwa mmecha ihu n'ime oke 125AARH-500AARH (3.2Ra ruo 12.5Ra). Enwere ike ịchọta mmecha ndị ọzọ na arịrịọ, dịka ọmụmaatụ 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra ma ọ bụ 6.3/12.5Ra. Oke 3.2/6.3Ra bụ nke a na-ahụkarị.

ỊKARA NA NKWAKỌTA

• Jiri ihe mkpuchi plastik chebe elu nke ọ bụla

• Maka igwe anaghị agba nchara niile, a na-etinye plywood n'ime akpa. Maka nnukwu nha, a na-eji plywood pallet jupụta carbon flange. Ma ọ bụ enwere ike ịhazi ngwugwu ahụ.

• Enwere ike itinye akara mbupu na arịrịọ

• A pụrụ ịkpụ ma ọ bụ bipụta akara na ngwaahịa. A na-anabata OEM.

NYOCHA

• Ule UT

• Ule PT

• Ule MT

• Nnwale nha

Tupu nnyefe, ndị otu QC anyị ga-ahazi ule NDT na nyocha nha. Ha nabatakwa TPI (nnyocha nke ndị ọzọ).

Usoro Mmepụta

| 1. Họrọ ezigbo ihe eji arụ ọrụ | 2. Bee ihe eji eme ihe | 3. Ịkpo ọkụ tupu oge eruo |

| 4. Ịkpụcha ihe | 5. Ọgwụgwọ okpomọkụ | 6. Ịrụ ọrụ siri ike |

| 7. Ịgwupụta ihe | 8. Ịmecha nke ọma | 9. Akara |

| 10. Nnyocha | 11. Nkwakọ ngwaahịa | 12. Nnyefe |

Ikpe Mmekọahụ

Ọrụ na mba Turkey, a na-eji flanges eme ihe na paịpụ gas eke. TUV kwadoro flanges ndị ahụ niile.

Mpempe akwụkwọ data Flange

1. Nha na nguzozi nke flange ga-adị ka ASME B16.5 si dị.

2. A ga-eji ihe e ji akpụ akpụ mepụta flanges.

3. Ihe ndị e ji rụọ ya ga-adị ka ọkọlọtọ ASTM A105, ASTM A694 F65 na ASTM A694 F70 si dị.

4. A ga-emenyụ ma mee ka flanges ASTM A694 F65 na ASTM A694 F70 dị nro.

5. A ga-enye asambodo nnwale ihe na akụkọ ọgwụgwọ okpomọkụ maka nyocha TPI.

6. Flanges WN ga-adị na nsọtụ bevel dịka ASME B16.25 si dị.

7. Ụkpụrụ nnwale kemịkalụ na igwe (mmetụta, mmepụta, nrụgide wdg) nke ihe ndị a ga-agbaso dịka ụkpụrụ ndị metụtara ya si dị.

8. A ga-eji mmanụ doro anya tee ihe niile dị n'elu ya ma tee ha mmanụ iji gbochie nchara ịcha.

9. Akara ga-agụnye ozi ndị a,

• Dayameta (oge 6")

• Klas nrụgide (ihe dị ka 150 LB)

• Ọkwa ihe (dịka ASTM A 105)

• Okpụrụ mgbidi (ihe dịka 4.78 mm)

• Nọmba Okpomọkụ (gwụchara 138413)

• Ụkpụrụ mmepụta (ASME B16.5)

10. Ihe ndị e ji rụọ ọrụ agaghị enwe ntụpọ na mgbawa ọ bụla n'elu ya. A machibidoro ịrụzi ihe ndị e ji agbado ọkụ kpamkpam.

11. A ga-ebuli flanges niile elu (RF) nwere elu mkpuchi. Elu mkpuchi ahụ ga-abụ Ra 3,2 – 6,3 µm (125 – 250 mic. inc.) dịka ASME B46.1 si dị.

12. A ga-akwakọba ihe ndị e ji arụ ọrụ iji gbochie mmebi na ihe ndị e ji emechi ihe.

13. Akụkụ niile ga-adị na nguzozi dị mma (+). E wezụga nguzozi, a machibidoro ya kpamkpam.

14. A ga-eme ka flange bevellings dabara na ASME B16.25.

15. A ga-enyocha usoro mmepụta ihe n'oge ọ bụla site na TPI.

16. TPI nwere ike iwere ihe nlele site na ihe ọ bụla maka ihe nlele kemịkalụ/nnwale igwe.

17. TPI ga-enyocha akụkọ nyocha na-abata.

| ihe | Nha (Inch) | Klas nrụgide | CS | ihe | WT (mm) | Ọnọdụ | Ọnụọgụ. |

| SORF | 12 | 150LB | 20 | A105 | - | Tankị Flanges | 48 |

| SORF | 8 | 150LB | 20 | A105 | - | Tankị Flanges | 32 |

| SORF | 3 | 150LB | 20 | A105 | - | Tankị Flanges | 32 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 14 | Tankị Flanges | 2 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 5.54 | Tankị Flanges | 4 |

| SORF | 20 | 150LB | 20 | A105 | - | Tankị Flanges | 6 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 5.54 | Tankị Flanges | 8 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 14 | Tankị Flanges | 8 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 16 | Tankị Flanges | 8 |

| SORF | 3 | 150LB | 20 | A105 | - | Tankị Flanges | 24 |

| SORF | 20 | 150LB | 20 | A105 | - | Tankị Flanges | 6 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 5.54 | Tankị Flanges | 8 |

| Flange, Olu Weld | 24 | 150LB | 20 | A105 | 14 | Tankị Flanges | 16 |

| ihe | Nha (Inch) | Klas nrụgide | CS | ihe | WT (mm) | Ọnọdụ | Ọnụọgụ. |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Olu Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Olu Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Olu Weld | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Olu Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Olu Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 2 |

| Flange, Olu Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 6 |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 4 |

| Flange, Olu Weld | 20 | 400LB | 62 | ASTM A694 F70 | 7.14 | PSM1 | 10 |

| Flange, Olu Weld | 12 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 4 |

| Flange, Olu Weld | 24 | 400LB | 62 | ASTM A694 F70 | 7.92 | PSM1 | 25 |

| Flange, Olu Weld | 4 | 400LB | 62 | ASTM A694 F70 | 4.78 | PSM1 | 16 |

| Flange, Olu Weld | 10 | 300LB | 51 | ASTM A694 F65 | 4.78 | PSB1 | 2 |

| Flange, Olu Weld | 6 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Olu Weld | 4 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 4 |

| Flange, Olu Weld | 18 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Olu Weld | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

| Flange, Olu Weld | 8 | 300LB | 51 | ASTM A694 F65 | 4.78 | RABIGH | 2 |

Ihe ndị dị mkpa maka paịpụ bụ ihe ndị dị mkpa na sistemụ paịpụ, a na-eji ha ejikọ, na-emegharị ya, na-agbanwe ya, na-agbanwe nha ya, na-emechi ma ọ bụ na-achịkwa mmiri mmiri. A na-ejikarị ha eme ihe n'ọhịa dịka ihe owuwu, ụlọ ọrụ mmepụta ihe, ike na ọrụ obodo.

Ọrụ Ndị Dị Mkpa:Ọ nwere ike ịrụ ọrụ dịka ijikọ paịpụ, ịgbanwe ụzọ mmiri si aga, kewaa na ijikọ mmiri si aga, ịgbanwe dayameta paịpụ, mechie paịpụ, ijikwa na ịchịkwa mmiri si aga.

Oke Ngwa:

- Mmiri na draịva ụlọ:A na-eji ikpere aka PVC na PPR tris eme ihe maka netwọk ọkpọkọ mmiri.

- Paịpụ ndị ọrụ mmepụta ihe:A na-eji ihe mkpuchi ígwè anaghị agba nchara na ihe mkpuchi ígwè alloy eme ihe iji bufee ihe mkpuchi kemịkalụ.

- Njem ike:A na-eji ihe ndị e ji ígwè rụọ arụ ọrụ nke nwere nrụgide dị elu na paịpụ mmanụ na gas.

- HVAC (Ịkpo oku, ikuku ikuku, na ntụ oyi):A na-eji ihe ndị e ji ejikọta paịpụ ọla kọpa iji jikọọ paịpụ ndị na-eme ka mmiri dị jụụ, a na-ejikwa njikọ ndị na-agbanwe agbanwe eme ihe maka ibelata ịma jijiji.

- Ịgba mmiri n'ugbo:Njikọ ngwa ngwa na-eme ka mgbakọ na mwepụ nke sistemụ ịgba mmiri sprinkler dị mfe.