Nkọwapụta

| Aha Ngwaahịa | oghere njikọta ihe |

| Nha | 1/2"-24" |

| Nrụgide | 150#-2500#,PN0.6-PN400,5K-40K |

| Ọkọlọtọ | ANSI B16.5, EN1092-1, JIS B2220 wdg. |

| Ọkpụrụkpụ mgbidi | SCH5S, SCH10S, SCH10, SCH40S, STD, XS, XXS, SCH20, SCH30, SCH40, SCH60, SCH80, SCH160, XXS na ndị ọzọ. |

| ihe | Igwe anaghị agba nchara:A182F304/304L, A182 F316/316L, A182F321, A182F310S, A182F347H, A182F316Ti, 317/317L, 904L, 1.4301, 1.4307, 1.4401, 1.4571, 1.4541, 254Mo na wdg. |

| Igwe carbon:A105, A350LF2, S235Jr, S275Jr, St37, St45.8, A42CP, A48CP, E24, A515 Gr60, A515 Gr 70 wdg. | |

| Igwe anaghị agba nchara duplex:UNS31803, SAF2205, UNS32205, UNS31500, UNS32750, UNS32760, 1.4462, 1.4410, 1.4501 na ndị ọzọ. | |

| Ígwè ọkpọkọ:A694 F42, A694F52, A694 F60, A694 F65, A694 F70, A694 F80 wdg. | |

| Ngwongwo nickel:inconel600, inconel625, inconel690, incoloy800, incoloy 825, incoloy 800H, C22, C-276, Monel400, Alloy20 wdg. | |

| Ngwakọta Cr-Mo:A182F11, A182F5, A182F22, A182F91, A182F9, 16mo3, 15Crmo, wdg. | |

| Ngwa | Ụlọ ọrụ mmanụ ala; ụlọ ọrụ ụgbọelu na ụgbọ elu; ụlọ ọrụ ọgwụ; ikuku gas; ụlọ ọrụ ike; ụlọ ọrụ ụgbọ mmiri; ọgwụgwọ mmiri, wdg. |

| Uru | ngwaahịa dị njikere, oge nnyefe ngwa ngwa; dị na nha niile, ahaziri ahazi; mma dị elu |

Ụkpụrụ Nha

NKỌWA NGWA AHỊA

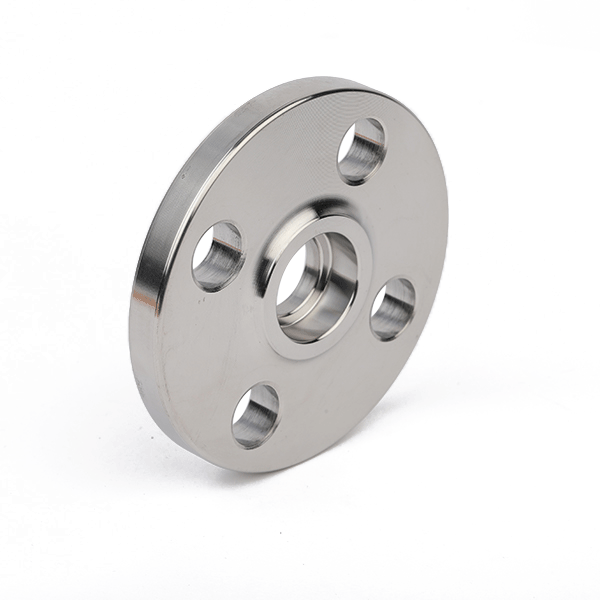

1. Ihu

Enwere ike ibuli ihu elu (RF), ihu zuru oke (FF), nkwonkwo mgbanaka (RTJ), Groove, Ire, ma ọ bụ ahaziri ya.

2. Socket weld

3. CNC emechara nke ọma

Mmecha ihu: A na-atụ mmecha ihu flange dị ka Arithmetical Average Roughness Height (AARH). A na-ekpebi mmecha ahụ site na ọkọlọtọ ejiri. Dịka ọmụmaatụ, ANSI B16.5 na-akọwa mmecha ihu n'ime oke 125AARH-500AARH (3.2Ra ruo 12.5Ra). Enwere ike ịchọta mmecha ndị ọzọ na arịrịọ, dịka ọmụmaatụ 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra ma ọ bụ 6.3/12.5Ra. Oke 3.2/6.3Ra bụ nke a na-ahụkarị.

ỊKARA NA NKWAKỌTA

• Jiri ihe mkpuchi plastik chebe elu nke ọ bụla

• Maka igwe anaghị agba nchara niile, a na-etinye plywood n'ime akpa. Maka nnukwu nha, a na-eji plywood pallet jupụta carbon flange. Ma ọ bụ enwere ike ịhazi ngwugwu ahụ.

• Enwere ike itinye akara mbupu na arịrịọ

• A pụrụ ịkpụ ma ọ bụ bipụta akara na ngwaahịa. A na-anabata OEM.

NYOCHA

• Ule UT

• Ule PT

• Ule MT

• Nnwale nha

Tupu nnyefe, ndị otu QC anyị ga-ahazi ule NDT na nyocha nha. Ha nabatakwa TPI (nnyocha nke ndị ọzọ).

Usoro Mmepụta

| 1. Họrọ ezigbo ihe eji arụ ọrụ | 2. Bee ihe eji eme ihe | 3. Ịkpo ọkụ tupu oge eruo |

| 4. Ịkpụcha ihe | 5. Ọgwụgwọ okpomọkụ | 6. Ịrụ ọrụ siri ike |

| 7. Ịgwupụta ihe | 8. Ịmecha nke ọma | 9. Akara |

| 10. Nnyocha | 11. Nkwakọ ngwaahịa | 12. Nnyefe |

Ajụjụ Ndị A Na-ajụkarị

1. Gịnị bụ ANSI B16.5 nke e ji igwe anaghị agba nchara rụọ?

ANSI B16.5 Forged Steel Stainless Socket Weld Flange bụ flange eji ejikọta paịpụ na ngwa nrụgide dị elu. E ji ígwè anaghị agba nchara rụọ ya, ya na njikọ socket maka ntinye dị mfe.

2. Kedu ka ANSI B16.5 si dị iche na ụdị flange ndị ọzọ?

N'adịghị ka ụdị flange ndị ọzọ, flange ANSI B16.5 nke ejiri ígwè anaghị agba nchara mepụta chọrọ njikọ socket weld ebe a na-etinye paịpụ ahụ n'ime flange ma jikọta ya n'ime. Nke a na-enye njikọ siri ike ma na-anaghị agbapụta.

3. Kedu uru dị na iji flanges ANSI B16.5 nke e ji igwe anaghị agba nchara rụọ?

Uru dị mkpa nke iji ANSI B16.5 forged steel socket weld flanges gụnyere ike dị elu, ntụkwasị obi na ezigbo iguzogide nchara. Ha dị mma maka ngwa ndị chọrọ njikọ siri ike ma sie ike.

4. Kedụ ụlọ ọrụ ndị na-ejikarị ANSI B16.5 eme ihe maka ịgbado ọkụ oghere igwe anaghị agba nchara?

A na-ejikarị ANSI B16.5 eme ihe n'ụlọ ọrụ mmanụ na gas, petrochemical, kemịkalụ, mmepụta ike na ụlọ ọrụ ọgwụgwọ mmiri. Ha dabara adaba maka nrụgide dị elu na ojiji okpomọkụ dị elu.

5. Enwere ike iji flanges ANSI B16.5 nke e ji igwe anaghị agba nchara rụọ arụ ọrụ na gas na mmiri mmiri?

Ee, enwere ike iji ANSI B16.5 forged steel socket weld flanges maka gas na mmiri mmiri. Emebere ha ka ha nwee njikọ dị nchebe ma nwee ike iguzogide nrụgide na okpomọkụ nke ọtụtụ mmiri mmiri.

6. Kedu ụkpụrụ ndị a na-agbaso maka imepụta flanges ANSI B16.5 nke ejiri ígwè anaghị agba nchara rụọ?

A na-emepụta ANSI B16.5 Forged Steel Stainless Socket Weld Flanges dịka ọkọlọtọ nke American National Standards Institute (ANSI) guzobere si dị. Ụkpụrụ ndị a na-eme ka flanges ndị ahụ mezuo ihe achọrọ maka ịdị mma na arụmọrụ.

7. Enwere ike iji ANSI B16.5 kpụọ ihe mkpuchi socket ígwè anaghị agba nchara n'ụdị nha na ọkwa nrụgide dị iche iche?

Ee, enwere ike iji ANSI B16.5 kpụọ ihe mkpuchi socket ígwè anaghị agba nchara n'ọtụtụ nha na ọkwa nrụgide dị iche iche. Nke a na-enye ohere maka mgbanwe na ndakọrịta na sistemụ paịpụ dị iche iche na ihe achọrọ.

8. Enwere ike iji flanges ANSI B16.5 nke e ji igwe anaghị agba nchara rụọ maka njikọ elu na nke dị larịị?

Ee, enwere ike iji ANSI B16.5 kpụọ ihe mkpuchi socket ígwè anaghị agba nchara maka njikọ ihu na ihu dị larịị. Enwere ike ịhazi ihu flange ka ọ dabara na mkpa nke ngwa ahụ.

9. ANSI B16.5 ò nwere ike iji ihe mkpuchi socket ígwè eme ihe nke ọma maka ojiji okpomọkụ dị elu?

Ee, flanges ANSI B16.5 nke e ji ígwè anaghị agba nchara rụọ dabara adaba maka ojiji okpomọkụ dị elu. E mere ha ka ha nagide okpomọkụ dị elu na-enweghị mmetụta nke ịdị ọcha ha.

10. Kedu otu esi etinye flanges ANSI B16.5 nke ejiri igwe anaghị agba nchara rụọ?

A ga-etinye flanges ANSI B16.5 nke e ji ígwè anaghị agba nchara rụọ n'ụzọ e si etinye paịpụ ahụ n'ime ihe e ji agbanye oghere ma jikọta ya n'ime ya. Ọ dị mkpa ijide n'aka na e nwetara njikọ kwesịrị ekwesị iji nọgide na-enwe ike na iguzosi ike n'ezi ihe.

Ngosipụta zuru ezu nke ngwaahịa

1. Ihu

Enwere ike ibuli ihu elu (RF), ihu zuru oke (FF), nkwonkwo mgbanaka (RTJ), Groove, Ire, ma ọ bụ ahaziri ya.

2. Socket weld

3. CNC emechara nke ọma

Mmecha ihu: A na-atụ mmecha ihu flange dị ka Arithmetical Average Roughness Height (AARH). A na-ekpebi mmecha ahụ site na ọkọlọtọ ejiri. Dịka ọmụmaatụ, ANSI B16.5 na-akọwa mmecha ihu n'ime oke 125AARH-500AARH (3.2Ra ruo 12.5Ra). Enwere ike ịchọta mmecha ndị ọzọ na arịrịọ, dịka ọmụmaatụ 1.6 Ra max, 1.6/3.2 Ra, 3.2/6.3Ra ma ọ bụ 6.3/12.5Ra. Oke 3.2/6.3Ra bụ nke a na-ahụkarị.

Akara na nkwakọ ngwaahịa

• Jiri ihe mkpuchi plastik chebe elu nke ọ bụla

• Maka igwe anaghị agba nchara niile, a na-etinye plywood n'ime akpa. Maka nnukwu nha, a na-eji plywood pallet jupụta carbon flange. Ma ọ bụ enwere ike ịhazi ngwugwu ahụ.

• Enwere ike itinye akara mbupu na arịrịọ

• A pụrụ ịkpụ ma ọ bụ bipụta akara na ngwaahịa. A na-anabata OEM.

Nnyocha

• Ule UT

• Ule PT

• Ule MT

• Nnwale nha

Tupu nnyefe, ndị otu QC anyị ga-ahazi ule NDT na nyocha nha. Ha nabatakwa TPI (nnyocha nke ndị ọzọ).

Usoro mmepụta

| 1. Họrọ ezigbo ihe eji arụ ọrụ | 2. Bee ihe eji eme ihe | 3. Ịkpo ọkụ tupu oge eruo |

| 4. Ịkpụcha ihe | 5. Ọgwụgwọ okpomọkụ | 6. Ịrụ ọrụ siri ike |

| 7. Ịgwupụta ihe | 8. Ịmecha nke ọma | 9. Akara |

| 10. Nnyocha | 11. Nkwakọ ngwaahịa | 12. Nnyefe |

Ihe ndị dị mkpa maka paịpụ bụ ihe ndị dị mkpa na sistemụ paịpụ, a na-eji ha ejikọ, na-emegharị ya, na-agbanwe ya, na-agbanwe nha ya, na-emechi ma ọ bụ na-achịkwa mmiri mmiri. A na-ejikarị ha eme ihe n'ọhịa dịka ihe owuwu, ụlọ ọrụ mmepụta ihe, ike na ọrụ obodo.

Ọrụ Ndị Dị Mkpa:Ọ nwere ike ịrụ ọrụ dịka ijikọ paịpụ, ịgbanwe ụzọ mmiri si aga, kewaa na ijikọ mmiri si aga, ịgbanwe dayameta paịpụ, mechie paịpụ, ijikwa na ịchịkwa mmiri si aga.

Oke Ngwa:

- Mmiri na draịva ụlọ:A na-eji ikpere aka PVC na PPR tris eme ihe maka netwọk ọkpọkọ mmiri.

- Paịpụ ndị ọrụ mmepụta ihe:A na-eji ihe mkpuchi ígwè anaghị agba nchara na ihe mkpuchi ígwè alloy eme ihe iji bufee ihe mkpuchi kemịkalụ.

- Njem ike:A na-eji ihe ndị e ji ígwè rụọ arụ ọrụ nke nwere nrụgide dị elu na paịpụ mmanụ na gas.

- HVAC (Ịkpo oku, ikuku ikuku, na ntụ oyi):A na-eji ihe ndị e ji ejikọta paịpụ ọla kọpa iji jikọọ paịpụ ndị na-eme ka mmiri dị jụụ, a na-ejikwa njikọ ndị na-agbanwe agbanwe eme ihe maka ibelata ịma jijiji.

- Ịgba mmiri n'ugbo:Njikọ ngwa ngwa na-eme ka mgbakọ na mwepụ nke sistemụ ịgba mmiri sprinkler dị mfe.

-

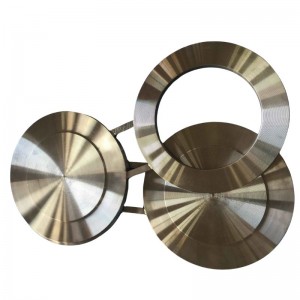

Din dn800 flange en10921 pn40 pn6 carbon ígwè ...

-

Carbon Steel e ji ígwè rụọ nke a na-akpọ ASME b16.36 wn orifice flan...

-

Njikọta ígwè welitere flange ihu EN1092-1 ụdị0 ...

-

Socket weld flange A105 carbon steel SW RTJ 3/4...

-

ASME b16.48 Ụlọ Ahịa Ngwaahịa Carbon Steel 8 ...

-

Skru BSP DIN PN 10/16 carbon steel A105 flange...